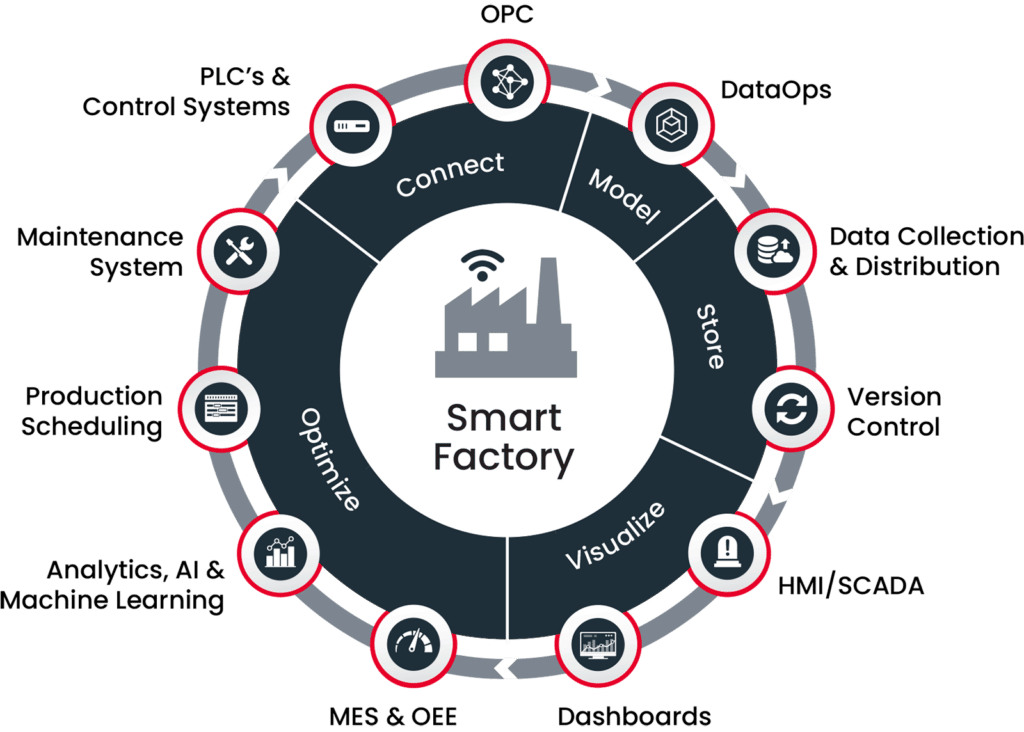

We have always helped our customers to

store, structure and transfer data into knowledge

We have been in the business since 1986 and we deliver, together with our partners, industrial solutions based on standard products and components, with the ability to meet market challenges by being able to control and optimize production processes.

The Novotek Group has the same ambition in all countries in which we operates and we aim to give our customers better solutions, faster support and a wider product portfolio in all our areas so they can stay competitive. Cross-border collaboration also makes our organisation more efficient and uniform, which help us to meet our goal and commitment: to deliver the RIGHT solution for every single customer in our field of expertise.

Our core values are summarized in the word CARE. CARE is an acronym for Competent, Agile, Reliable and Enthusiastic. These words describe very well the feeling the customers and we ourselves have about us.