Production is Evolving… Do you Have the Insights to Keep Up?

“This story was originally published by Matt Wells GE Digital

and has been republished here with permission.”

One thing is becoming more and more evident every day -data drives today’s operations. Manufacturers globally are ranking data analytics as one of their top three priorities and believe that the power of data holds the key to shifting their industry’s competitive landscape. Many organizations fear that, without the implementation of a data analytics strategy, competitors will gain market share at their expense.

Manufacturers are tasked with meeting production targets while also keeping costs and risk under control. At the same time, customer demands pressure companies to quickly change lines, shift resources to new products, and find the capacity to produce what the market wants, when it wants it—all without compromising quality.

Meanwhile, there is a widening talent gap, which forces manufacturers to replace experienced professionals with a younger, more tech-savvy—but less seasoned—workforce. And the possibility of unexpected downtime, not to mention rapidly fluctuating commodity prices, constantly looms, threatening to throw plans into disarray.

But the real, major shift is the rapidly contracting window between market demand and completed production. In the past, companies had the luxury of months or years to line up facilities. But, it’s no longer a make-to-stock world. Now, organizations are competing based on their ability to manufacture to order.

Data is scattered across the organization, making it difficult to share and use. Although point products have automated certain tasks, these systems are not connected, so it’s difficult to share information or view a feedback loop. This leaves manufacturers reacting to emergency situations rather than proactively avoiding them through predictive diagnosis and preventative maintenance.

Consistent Metrics

It’s Time for a New Approach

Relying on process and equipment expertise that resides solely in a few key individuals’ heads doesn’t allow manufacturers to act with required speed. This human-based knowledge needs to be turned into a digital asset. That means tracking the flow of data with consistent metrics that span all facilities. It also means that learnings from one plant need to be shared with all of facilities to make sure an insight uncovered at one location benefits the entire enterprise.

What if you could…

- Run adaptable facilities that use information to adjust your materials, equipment, people, and processes as necessary?

- Start a new initiative with the foundation already completed?

- Deliver insights to the right people at the right time?

If you could, you’d be well positioned to help executives view data across multiple facilities, to identify and resolve inefficiencies, and locate available capacity. You could help plant managers monitor lines from a single screen, enabling them to spot trouble before it happens. And you’d be able to give operators the information they need to run equipment at maximum efficiency and perform proactive repairs before a failure shuts down a line.

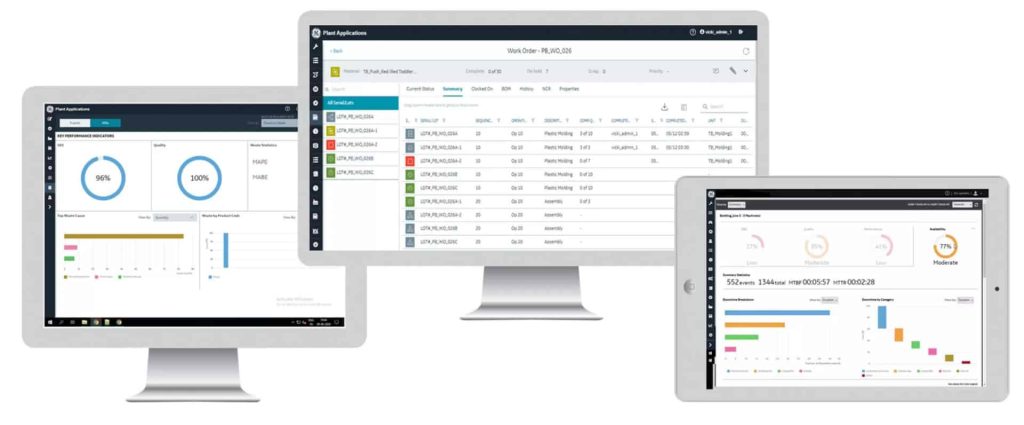

Proficy Plant Applications is the industry’s first Manufacturing Execution System (MES) that seamlessly spans process, discrete and mixed manufacturing environments, allowing manufacturers to efficiently deploy one MES across their enterprise.

Work from a Complete Foundation

A manufacturer’s strong suit is making products, but it may not be writing applications and managing data. GE Digital’s Digital Plant Software and domain expertise can help manufacturers to track data across multiple plants, equipment, materials, and people. This foundation allows them to immediately measure and compare equipment metrics and operator practices to expose the reasons for production losses—without making internal IT investments or adding high-priced professionals to permanent staff.

When companies make information an enterprise-wide asset, manufacturers are able to use best practices to extract the right equipment and quality data from operations and share this information broadly across the organization.

Mission critical software contains proven, standardized data templates to specify which metrics to track across all equipment to make sure the data remains consistent and can easily roll up to production results across all lines and plants. Pairing this information with role-specific dashboards creates views customized to the individual needs of operators, plant managers, or executives across the organization.

And, because no individual, piece of equipment, or bit of data lives in isolation, software can define the relationships between each element of the production process, essentially creating a digital representation of the plants, a Digital Twin. So, the next time a machine goes down, you’ll be ready to quickly spot the equipment, operators, and processes that will be impacted.

Finally, adapting facilities on the fly in response to reading signals from the market and synchronizing output accordingly. Manufacturers can use information, provided by software that applies the visibility they need to quickly generate a new bill of materials, reroute components, change equipment schedules, and re-assign employees.

GE Digital’s Plant Operations Software also closely monitors the production process to catch deviations and adjust equipment before the product is created, helping to avoid wasted materials. And because the software supports traceability across the full scope of the production process, companies can build a more complete understanding of the nuances of operations. This way, they can visualize how a change at the master level will impact specific lines and finished goods, or quickly backtrack to identify and isolate the root cause of a component or material issue.

/ Matt Wells

Vice President, Product Management, GE Digital

Matt Wells has 20 years of experience with industrial automation and operations management software. He is responsible for leading Product Management for GE Digital’s Manufacturing and Digital Plant business and understands that uptime is critical. Matt has worked with customers in a wide variety of industries including life sciences, food and beverage, automotive, metals, and pulp and paper.